HOTLINE: +840902720814

Wedge gate valve is a linear motion, multi-turn general service valve.

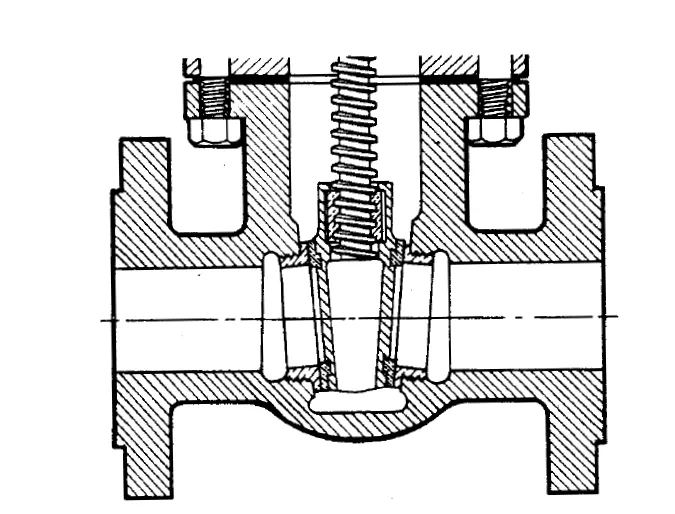

ZECO wedge gate valve is one of the gate valve types. Wedge gate valves are named because the two sealing surfaces resemble wedges in the body. In general, the two wedge gate valve sealing surface and the Angle of the vertical center line of 2 ° 52 ‘, 3 ’30 °, 5 °, 8 °, and so on. Wedge gate valves can be divided into rising stem gate valve and non-rising stem gate valve according to the stem structure, and wedge gate valve and double disc gate valve according to the gate structure. ZECO is a professional gate valve manufacturer in China, with nearly 30 years of experience and history in the production of gate valves.

he solid, or single wedge gate valve is the most widely used and the lowest cost used-type in the process industry for oil, gas and air services. The purpose of the wedge shape is to introduce a high supplementary seating load. Solid-Wedge Gate Valve can be installed in any position, suitable for almost all fluids and practical for turbulent flow services.

In some situations, the valve cannot be reopened until the system temperature reheats the valve; this phenomenon is known as “Thermal blinding”. Wedge gate valves can be further described as inside screw or outside screw patterns. Solid wedge gate valves in waterworks industry are popular as Sluice valves.

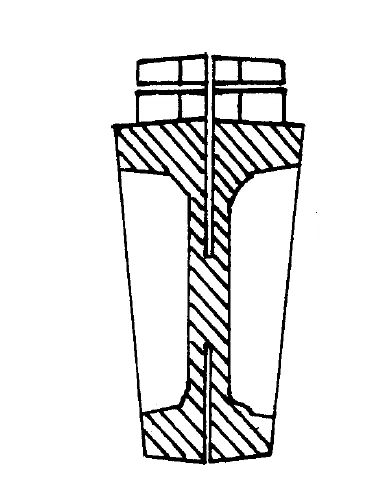

The flexible wedge is a one-piece solid disk with a cut around the perimeter. These cuts vary in size, shape, and depth. A shallow, narrow cut on the wedge perimeter gives less flexibility but retains strength. A cast-in recess or deeper and wider cut on the wedge perimeter gives more flexibility but compromises the strength.

This design improves seat alignment and offers better leak tightness. It also improved performance in situations where thermal binding possible. Flexible wedges Gate valves are used in steam systems.

Suitable for general application as on/off and isolation valves, not recommended for throttling and/or regulating purposes. They have excellent resistance to earthquake, shocks, vibration, pressure & strokes and can be operated soundly between -196°C to 595°C.

| No | Part | Material |

| 1 | Body | ASTM A216 WCB |

| 2 | Seat Ring | ASTM A105 + 13Cr |

| 3 | Wedge | ASTM A216 WCB + 13Cr |

| 4 | Stem | ASTM A276 410 |

| 5 | Bonnet Gasket | Graphite + SS304 |

| 6 | Bonnet Bolt | ASTM A193 B7 |

| 7 | Bonnet Nut | ASTM A194 2H |

| 8 | Bonnet | ASTM A216 WCB |

| 9 | Backseat | ASTM A182 F6a |

| 10 | Stem Packing | Reinforced Graphite |

| 11 | Handwheel | KTH330-08 |

| CERTIFICATE NAME | INSTITUTION |

| API 600-0351 | American Petroleum Institute |

| API 6D-1225 | American Petroleum Institute |

| ISO 9001:2015 | TQCS INTERNATIONAL (GROUP) PTY LTD\ |

| ISO 14001:2015 | TQCS INTERNATIONAL (GROUP) PTY LTD\ |

| ISO 45001:2018 | TQCS INTERNATIONAL (GROUP) PTY LTD\ |

| Fire Test Certificate API 6FA | TUV SUD SERVICE GMBH |

| CE-2810 | PRESSURE EQUIPMENT DIRECTIVE 2014/68/EU |

Nhập email của bạn để nhận thông báo sớm nhất của chúng tôi